ID Partner at Chemspec Europe!

We’re delighted to be taking part in Chemspec Europe, and to see you on June 4 and 5, 2025 in Cologne, in the area dedicated to new exhibitors!

After our presence at Tech&Fest 2025, we’re continuing to pursue our goal of offering you solutions tailored to your projects, with clean, high-performance technologies that meet environmental challenges.

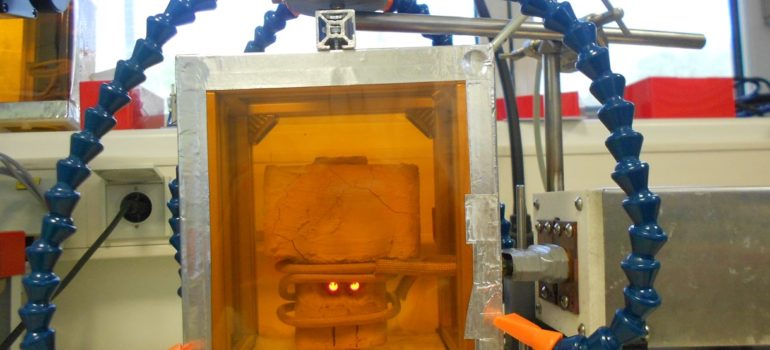

Come and discover induction for your chemical industry and laboratory applications.

We’d be delighted to talk to you about electrifying your processes to develop your business.