Induction is an innovative and non-contact electromagnetic heating technology that has several advantages such as high energy efficiency, controlled heating, high safety, and pollution-free. The objective of this article is to build up these and other advantages based on different scientific data about the performance of induction heating in the food industry. We believe that the companies that will apply induction heating in their procedures will have more versatility in sustainable food methods and will be able to face future challenges.

About Induction heating

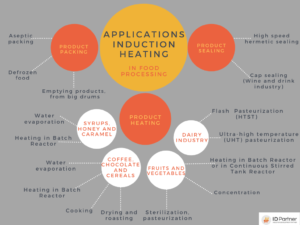

The induction system (generator + coil) will generate a magnetic field that induces a current in the conductive material (reactor vessel), which will rise in temperature. Induction heating works only with conductive and ferrous materials. Depending on the material’s magnetic permeability and ferromagnetic properties, various metallic materials, such as steel, cast iron, among others, could be heated by induction.[1] Non-magnetic conductive materials can also be heated with a lower efficiency.[2] Induction heating is seen as an ideal technology for pasteurizing liquid foods, but the versatility of induction electric heaters makes it possible to use in various fields of food and beverage industry as is shown in the next image:

https://induction-partner.com/

https://induction-partner.com/

Induction heating has its advantages over the conventional heating systems (resistance, hot water, gas, steam, etc.) Since it is non-contact it is very efficient, and the heat is generated inside the work-piece (sample) this means direct heating of metal surface without thermal inertia and no conduction loss.[3] And since induction requires no warm-up or cool-down cycle, make it highly compatible with energy-efficient automated systems. Read the complete article to find out the 5 most important facts about Induction Heating in the food industry.

1. Induction heating improves the quality of the food

Heat exchangers powered by induction have constant and direct heating to the flowing fluid, with a maximum uncertainty of ± 0.5 ° C [4] this avoids local high temperatures and is essential for controlling the reaction kinetics in the food industry.

The experimental result of R. Martel, Y. Pouliot[5] in the University Laval-Canada, comparing milk pasteurized by conventional heating and by induction heating, showed that when working, in a UHT pasteurization process, with induction heating we can avoid or regulate the Maillard reaction (Formation of flavours and browning compounds) this improves the sensory characteristics in the milk and dairy products. (For more data about dairy industry read Appendix A)

It was reported in another scientific paper in Brazil [6] that using ferritic stainless steel (common use in Induction heating systems) in sugar manufacture plants, has several advantages because this metal is chemically and biologically inert, does not affect taste or colour of the sugar and lower the risk of micro-organism colony growth.

2. Induction heating have good energy and exergy efficiency

Başaran’s experimental results show that the pasteurization system with induction heater needs less energy and exergy input than DPHE.(Exergy also called second law efficiency is the maximum useful work during a process)

Basaran et al. [7] and a group of engineers at the University of Celal Bayar-Turkey, compared in a pilot-scale, an induction heater pasteurization system with a DPHE (Double Pipe Heat Exchanger) pasteurization system, with electric boilers, to evaluate energy and exergy, they considered the same temperature increase in both systems from 65 to 110 ° C. After calculations, for both applications, it was found effectiveness or first law efficiency of heat transfer with the inductive heating system is 95.00% energy efficiency and 46.56% exergy efficiency while the conventional heating system with the electric boiler is 75.43% energy efficiency and 16.63% exergy efficiency. (Appendix B give more data about energy and exergy).

Thanks to these results, the engineers concluded that apply the inductive method in tomato pasteurization9, strawberry jam[8], milk, and honey pasteurization[9] is more efficient than the DPHE heating system. (To clarify this information, most factories run on fossil fuels, and fossil fuels are much less efficient, 40-65% effectiveness[10], than the commercial electrical method in this study.).

3. Induction system offers reduce the clogging in the system

Clogging due to the unwanted material accumulated on the tube surfaces of the heat exchangers is one of the main problems in the food industry, the gunk in the interior of these tubes severely decreases the mass flow rate through the tube bundle[11]. According to experimental results, this effect can be minimized using electromagnetic induction. R. Martel, Y. Pouliot5 discovered that working with induction the amount of protein on the heating surface is less. This improves cleaning efficiency, increasing production run length with a reduction in the cost of production capacity [12] and a reduction of the waste-water from the process[13].

https://chempds.blogspot.com/2018/12/types-of-fouling-in-heat-exchangers_18.html

https://chempds.blogspot.com/2018/12/types-of-fouling-in-heat-exchangers_18.html

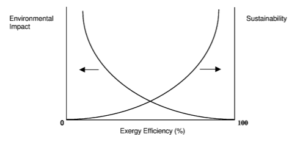

4. Induction installation are sustainable and have small carbon footprit

Nowadays the term “sustainability” is used to talk about everything, but it hasn’t really been defined very well. Rosen, Marc & Dincer, Ibrahim made a research about exergy efficiency and sustainability, in terms of several measures (order destruction and chaos creation, or resource degradation, or waste exergy emissions).[14] They conclude that the process can be” sustainable” if is energy and exergy efficient. In these terms we can said that work with induction decrease the associated environmental impact, because gives rise to better energetic and exergetic performance.

Knowing this, the food and beverage manufacturers that will works with induction have a significant opportunity to have “added value “ and sustainable products, working with a clean technology which will help in protecting the environment and decrease the carbon footprint of the food industry.

Rosen, Marc & Dincer, Ibrahim. (2001). Exergy as the confluence of energy, environment and sustainable development. Exergy, An International Journal. 1. 3-13.

Rosen, Marc & Dincer, Ibrahim. (2001). Exergy as the confluence of energy, environment and sustainable development. Exergy, An International Journal. 1. 3-13.

5. Induction installations improves working conditions for the employees

An induction system improves working conditions for the employees by eliminating smoke, waste heat, noxious emissions, and loud noise in the facilities (Induction only heats the material and not the workshop). Heating is safe and efficient with no open flame to endanger the operator; non-conductive materials are not affected and can be located close to the heating zone without damage.

There are no high pressure and no hot steam systems and so on can avoid any hazard with explosions like in 2016 in a dairy company in steam generator[15]. (In the ARIA database [16] you will find more than 300 high temperature-related events that have occurred in France.)

https://www.aria.developpementdurable.gouv.fr/wpcontent/files_mf/Gasboilersstudy_sept08

https://www.aria.developpementdurable.gouv.fr/wpcontent/files_mf/Gasboilersstudy_sept08

Conclusion

Induction heating is a clean technological innovation designed to save energy, leading to high productivity and efficiency. Induction heating offers repeatable quality and rapid, high intensity, contact less heat generation directly, and accurate on the surface of the work-piece.

Inside the design of induction heating in a process, there is a specialized integration of workers including mechanical, electrical, and chemical engineers that will ensure a customized solution with a unique and innovative procedure with a high level of reliability and durability.

Consumers in all the world are prepared for the food business to be significantly more sustainable so we encore you to think in apply Induction heating for your company to fulfil the challenge to move towards a decrease in the footprint of the food industry, focus on the 2030 Agenda for Sustainable Development. [17]

Sources

[1] Rudnev V, Loveless D, Cook R, Black M (2003) Handbook of induction heating. Marcel Dekker, INC., New York

[2] Pitot, P. (2020). Austenitic or ferritic stainless steel, induction heating efficiency. ID Partner “Application Notes,” 1. https://inductionpartner.com/en/blog/2020/05/05/austenitic-or-ferritic-stainless-steel-induction-heating-efficiency-2/

[3] Induction Heating: Its Applications In Dairy Industry Shashi Kumar, C.S and D.B. Puranik IJISET – International Journal of Innovative Science, Engineering & Technology, Vol. 3 Issue 3,

[4] Egalon, Julie and Caux, Stéphane and Maussion, Pascal and Souley, Majid and Pateau, Olivier Multi phase system for metal disc induction heating: modelling and RMS current control. (2012) IEEE

[5] R Martel, Y Pouliot, A Charette. Évaluation d’un chauffe-fluide par induction magnétique pour la pasteurisation du lait. Le Lait, INRA Editions, 1992, 72 (3), pp.297-306.

[6] El-Mashad, Hamed & Pan, Zhongli. (2016). Application of Induction Heating in Food Processing and Cooking. Food Engineering Reviews

[7] Başaran, Anıl & Yilmaz, Tuncay & Civi, Can. (2018). Application of inductive forced heating as a new approach to food industry heat exchangers: A case study—Tomato paste pasteurization. Journal of Thermal Analysis and Calorimetry.

[8] Başaran, Anıl & Yilmaz, Tuncay & Civi, Can. (2019). Energy and exergy analysis of induction‑assisted batch processing

in food production: a case study—strawberry jam production. Journal of Thermal Analysis and Calorimetry.

[9] Başaran, Anıl & Yilmaz, Tuncay & Civi, Can. (2019). Induction assisted pasteurization of honey. Journal of Thermal Analysis and Calorimetry.

[10]https://www.engineeringtoolbox.com/heat-recovery-efficiency-d_201.html

[11]http://www.processtechacademy.com/a-day-in-the-life-of-a-shell-and-tube-hex/

[12] Asselt, A.J. & Houwelingen, G. & Giffel, M.C.. (2002). Monitoring System for Improving Cleaning Efficiency of Cleaning-in-Place Processes in Dairy Environments. Food and Bioproducts Processing

[13] Quaiser, Jutta & Gilbert, Eva. (2016). Wastewater treatment in the dairy processing industry – recovering energy using anaerobic technology.

[14] Rosen, Marc & Dincer, Ibrahim. (2001). Exergy as the confluence of energy, environment and sustainable development. Exergy, An International Journal. 1. 3-13.

[15]https://www.aria.developpement-durable.gouv.fr/accident/48569_en/?lang=en